Introduction and Consideration

The primary application of penstocks is the flow control and isolation of fluids associated with water, sewage treatment plants, power generation irrigation schemes and process plant.

The modern penstock is designed to cater for a wide variety of duties from low seating to high off-seating heads in sizes from 150mm to over 5000mm square.

Selection of the correct penstock to suit the duty is important to satisfy the design criteria and provide the most cost effective solution.

Operation of the penstock is governed generally by factors outside the control of the penstock manufacturer. However, the range of H.C. Waterbeheersing Engineering Penstocks operating equipment is extensive: from simple direct operation by hand wheel to complex control systems for electrical, pneumatic or hydraulic actuation.

The range of penstocks with associated operating equipment will cater for the most demanding specification and application.

[vision_content_box style=”royal-blue” title=”Selection Considerations for Channel Mounted Penstocks”]

When setting out to determine the unit most suited to a particular requirement, the following considerations have to be made:

- Size of gate required.

- In which direction is the flow of the fluid to be controlled: will it force the door on to or away from its sealing face?

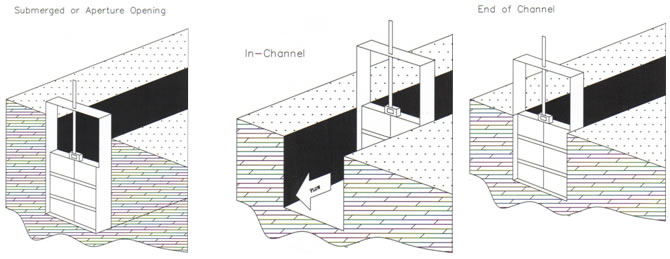

- Wall, channel mounting?

- Method of operation?

- What is the differential head in metres across the gate in each direction under:

a. Static conditions?

b. Opening and closing conditions?

[/vision_content_box]